FSW

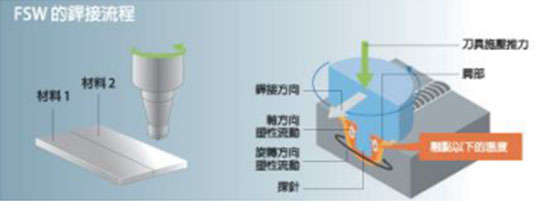

What is FSW?

Friction stir welding (FSW) is a solid-state welding technology; the principle is to use the high-speed rotating stirring head to generate heat energy by friction with the workpiece surface so that the material reaches a plastic state (below the melting point) in the joint area. After the material softens, the tool moves along the welding direction to complete the integration of the materials and form a defect-free, high-quality joint. Compared with traditional welding, FSW technology can make the material obtain better strength. Tung Shuhn Precision is a friction welding manufacturer and supplier you can trust.

Advantages of FSW

High-strength jointing:

The mechanical properties of the welded joint are close to or better than the parent material, with high strength and low defect rate.

Small deformation:

During the FSW process, the material only undergoes plastic deformation, and there is no need to add welding materials, which reduces pollution. It also avoids deformation caused by molten welding and improves the accuracy and quality of the workpiece.

Welding of different materials:

FSW is not only suitable for the same material but also achieves the joining of different materials, such as aluminium alloy and steel, copper alloy and titanium, and it can even weld plates of different thicknesses.

High efficiency and high quality:

The FSW process does not require pretreatment of the workpiece surface, the welding speed is fast, the efficiency is high, and the welded joint quality is stable.

Energy saving and environmental protection:

FSW is a low-energy welding method that does not require welding rods, fillers, or shielding gases, reduces resource waste and pollutant emissions, and protects the environment.

No need to remove oxide in advance:

There is no need to remove oxides from the workpiece surface before welding.

Fully automated:

The FSW welding process can be fully automated.

Application Scope

Regarding application scope, FSW is widely used in the automotive industry, such as in car bodies, hoods, bumpers, and aluminium rims. It is also commonly used in the semiconductor industry's ship hulls and decks, train bodies and bottoms, and cooling plates.

Automotive Industry:

Used to manufacture automobile bodies, engine hoods, bumpers, aluminium rims, and other parts to improve product strength and durability.

Aerospace Industry:

Used in the manufacture of aircraft and rocket structures, such as fuselages, decks, etc., as well as in the manufacture of cooling plates in the semiconductor industry.

Rail Transit:

Used in manufacturing structural parts such as train bodies and chassis, providing lightweight and high-strength solutions.

Electronics Industry:

Used for welding radiators, cooling plates, etc.

FSW Process

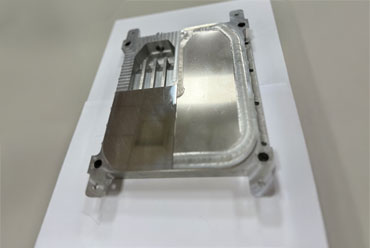

Application in the automotive electrification module parts

It can also be applied to manufacturing parts of electric vehicles (EVs), such as converters, batteries, motors, etc.

Electrification module parts

- Electrification module parts

- All-around welding, no need for filler material, and can increase workpiece durability.

Cooling plate of a power control part

Looking for a Professional Friction Stir Welding Company?

Contact Tung Shuhn Precision