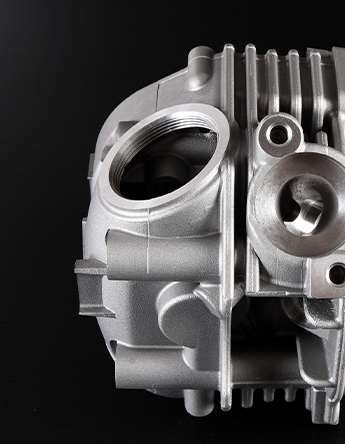

Casting : the cornerstone of precision manufacturing

Casting is a time-honoured and precise manufacturing process that by pouring molten metal or other material into a mould and letting it cool before forming into a specific shape. Casting is widely used to manufacture various metal components, including high-precision mechanical accessories. Metal casting services can be divided into three types:

Die Casting:

Commonly used for manufacturing small to medium-sized metal parts, suitable for complex and detailed components.

Gravity Casting:

Gravity or pressure fills material into the mould, which is suitable for larger parts with high-density requirements.

Sand Casting:

Sand core is used as a mould, suitable for manufacturing large, complex parts at lower costs and shorter production cycles.

Tung Shuhn Precision has extensive experience in casting and provides solutions for various casting methods. Whether you need die casting, gravity casting, or a sand casting process, we can provide the best manufacturing solutions to meet your needs and become your best metal casting partner. Please get in touch with us if you have any questions or needs regarding the casting process or our services.

We look forward to working with you to explore more possibilities for manufacturing innovation.