Tung Shuhn profile

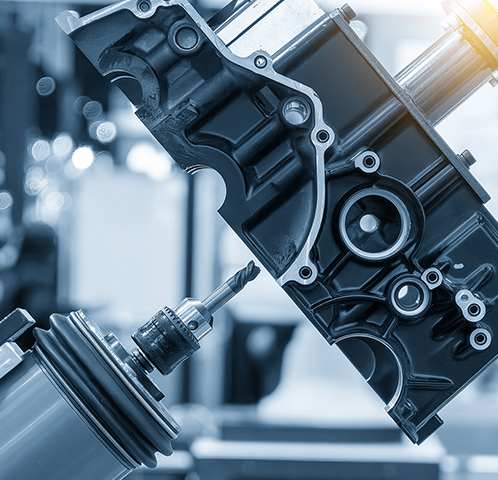

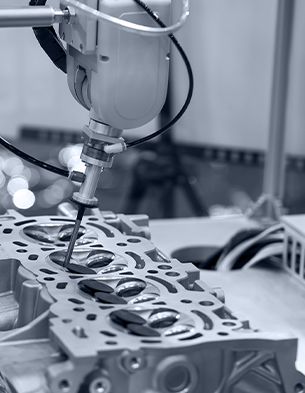

Tung Shuhn Precision Industry Co., Ltd. was established in 1986. Its headquarters are in Changhua County, Taiwan. The factory area is 8,500 square meters, and the land area is 11,000 square meters. It has five axes and various turning and milling machine processing equipment. It's the first in the industry to purchase Taiwan's first MAZAK FSW friction stir welding machine, and it has more than 100 machines in total.

The company was originally a manufacturer of stamping die parts. Since introducing advanced centre lathes and lathe equipment in 1999, we have gradually become a leading manufacturer of precision metal parts contractually. We have successfully obtained ISO 9001:2015 and IATF 16949:2016 certifications. We not only provide parts for well-known electric vehicle manufacturers such as TESLA and LUCID but are also an audited and certified manufacturer for Japan's SHOWA and HONDA and an important supplier for well-known brands such as GOGORO.

Who we are

Tung Shuhn Precision takes "quality first, continuous improvement, sustainable management" as its quality policy, upholds the business philosophy of "integrity, professionalism, innovation", and is committed to providing high-quality, high-value-added products and services to global customers. Our products cover:

Supplier of world-renowned electric vehicle manufacturers

Tung Shuhn Precision supplies world-renowned electric vehicle manufacturers and has established long-term cooperative relationships with well-known domestic and foreign companies such as GOGORO. With years of in-depth cooperation with the electric vehicle industry and technological accumulation, Tung Shuhn Precision has won a good reputation and customer trust in the global market and successfully occupied a place in the industry.

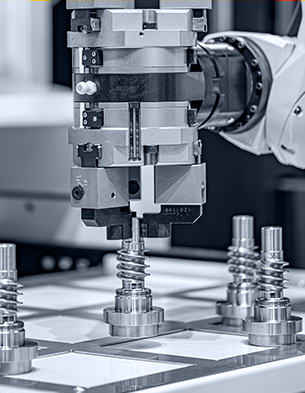

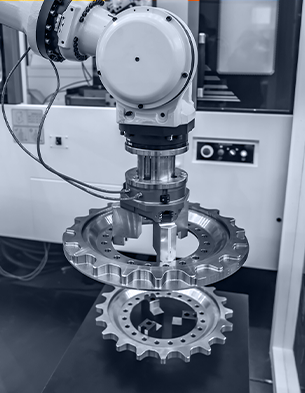

Tung Shuhn's advantages

Tung Shuhn Precision is a professional OEM manufacturer of precision metal parts with over 30 years of extensive experience in the industry. The company has won customers' unanimous trust with its strong technical strength, strict quality management, and perfect after-sales service. In the field of precision metal parts manufacturing, we have the following advantages: