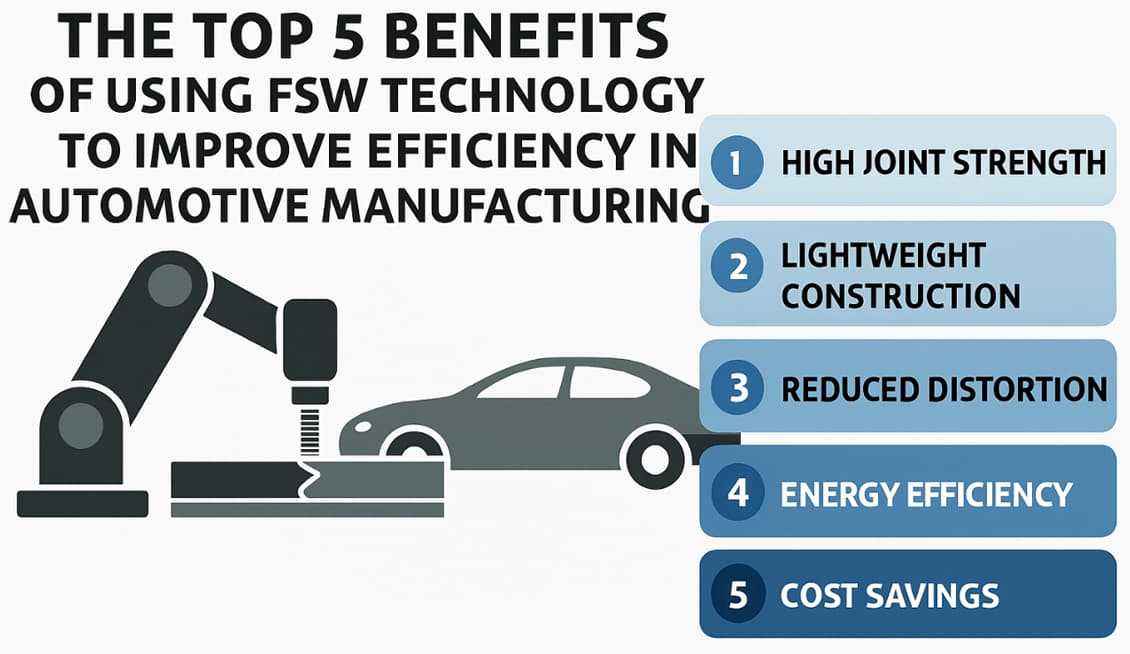

Five Advantages of Using FSW Technology to Improve Automotive Manufacturing Efficiency.

As the global manufacturing industry develops towards lightweight, high efficiency and low emissions, the automotive industry has an increasingly urgent need for innovative manufacturing technologies. Among them, Friction Stir Welding (FSW) has gradually become a popular choice for enhancing automotive manufacturing capabilities due to its non-melting welding characteristics. This article discusses the application of FSW technology in automotive manufacturing and its five key benefits in improving manufacturing efficiency.

1. The best solution for lightweight material welding

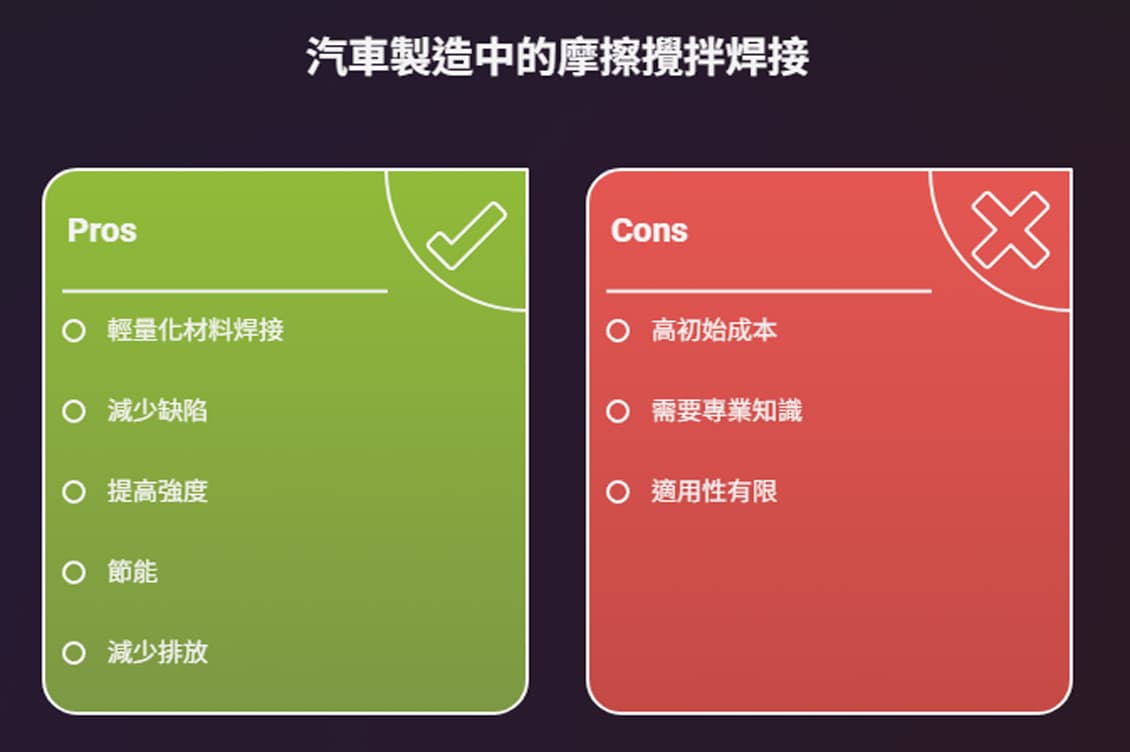

To reduce vehicle weight, lower fuel consumption, and improve energy efficiency, lightweight materials such as aluminium alloy and magnesium alloy are being increasingly used in automobile body parts. However, in traditional fusion welding technology, these metal materials are prone to cracks, pores or deformation due to high temperature, resulting in unstable welding quality. FSW technology heats the metal to a plastic state through the heat energy generated by friction, completes the material connection in the solid state, and avoids the common defects of fusion welding. This not only improves welding strength and reliability but also ensures the microstructural integrity of the material during the welding process, making the application of lightweight materials more extensive and safer.

Practical Benefits:

- The total weight of the vehicle is significantly reduced, improving fuel efficiency.

- Effectively avoid quality problems caused by material defects.

2. Improve welding quality and joint performance

The structural and high-strength load-bearing components of automobile bodies have extremely high requirements for the quality of their welded joints. FSW technology maintains the welding area in a solid state, and the joint performance is comparable to or even exceeds that of the original parent material. At the same time, its fatigue resistance and corrosion resistance are significantly superior to those of traditional welding technology. In contrast, traditional arc welding or laser welding is prone to generating microcracks or residual stress during the welding process, which affects the stability of the joint. FSW can minimise the stress concentration problem at the joint and improve the durability and safety performance of the vehicle in harsh environments.

Practical Benefits:

- Avoid potential safety hazards caused by weak weld joints.

- Reduce repair and replacement costs for vehicle fatigue damage.

3. Fully automated production, improving efficiency and productivity

FSW technology is suitable for the design requirements of automated production lines. Its welding process is controlled by machine automation, and it can continuously and stably perform high-quality welding. Compared to traditional welding, FSW does not require filler materials and is easy to operate, which significantly shortens the production cycle and reduces the error rate associated with manual operation. Additionally, FSW technology is well-suited for welding parts with long distances and complex geometric structures, particularly in the production of components such as automobile door frames, chassis structures, and aluminium car bodies. Its efficiency far exceeds that of traditional welding methods, which involve multiple processes.

Practical Benefits:

- Improve the degree of automation of production lines and reduce workforce requirements.

- Accelerate the production of vehicle parts and shorten the delivery cycle.

4. Energy and Material Cost Savings

FSW technology is a highly energy-efficient welding method that requires only localised heat generated by friction, eliminating the need for additional high-energy radiation or electricity. Furthermore, FSW requires no additional materials, such as filler materials or shielding gas, which significantly reduces consumables and effectively lowers production costs. Furthermore, FSW technology offers extremely low wear and tear, eliminating the need for manual grinding and secondary processing, leading to a more streamlined and environmentally friendly production chain, ultimately achieving comprehensive cost and resource savings.

Practical Benefits:

- Reduced welding costs per vehicle, enhancing competitiveness.

- Reduced energy and material waste, aligning with the trend toward green manufacturing.

5. Reduce the risk of body deformation and welding defects

During the high-temperature heating process of traditional welding, the metal around the weld is easily deformed due to the instantaneous thermal expansion effect, which increases the difficulty and cost of correcting the product. The low-temperature process of FSW effectively avoids the situation of large-area heat input and can significantly reduce welding strain and residual stress. At the same time, the entire welding process of FSW technology produces less smoke and splash, resulting in a lower environmental impact, and can effectively improve working conditions and production efficiency.

Practical Benefits:

- Improve the processing accuracy of vehicle parts and reduce the rework rate.

- Reduce the cost of vehicle structure deformation correction.

To recapitulate, the application of friction stir welding (FSW) technology in automobile manufacturing is bringing revolutionary changes to the industry. It not only meets the manufacturing needs of lightweight, automation, and high quality, but also continues to attract the industry's attention by saving energy resources and reducing welding defects. For automobile manufacturers seeking comprehensive improvements in efficiency, cost, and quality, FSW has undoubtedly become an indispensable and vital technology.

The potential of FSW technology will be further realised with the continuous upgrading of the automobile industry. As an expert in the field of automation and precision machining, Tung Shuhn Precision will continue to be committed to providing leading FSW solutions for the automotive industry, leveraging its efficient technical strength and rich experience to help customers reach a new peak of manufacturing efficiency.