Eco-friendly Manufacturing of EV Parts: Tung Shuhn's Circular Economy Practices and Low-carbon Supply

Facing the ESG challenges of the global electric vehicle boom, Tung Shuhn Precision, with its core focus in Taiwan, is deeply engaged in environmentally friendly manufacturing of electric vehicle parts. Through innovative practices such as material recycling, waste reduction, and green packaging, we achieve a low-carbon, efficient circular economy, supporting your green supply chain strategy.

The global automotive industry is undergoing an accelerated transformation. The rise of electric vehicles (EVs) is not only changing transportation patterns but also directly impacting the sustainability standards of the supply chain. Consumers and regulators are increasingly concerned about the carbon footprint of products and the ESG (environmental, social, and governance) performance of companies. As Taiwan's leading EV parts manufacturer, Tung Shuhn Precision understands our responsibility not only to provide superior product performance but also to lead a green revolution in environmentally friendly manufacturing. Through solid circular economy practices, we aim to inject sustainable momentum into the EV industry in Taiwan and globally.

Control from the source - precise regeneration of material recycling

The lightweighting of electric vehicles relies on high-performance aluminium alloys. However, traditional aluminium production processes consume enormous amounts of energy. Tung Shuhn Precision promotes the use of a high proportion of recycled aluminium in the manufacture of electric vehicle parts and has established a sophisticated and efficient material recycling system.

Aluminium alloy scrap generated during the production process is rigorously sorted, refined, and reintegrated into the production cycle. This "aluminium alloy recycling" mechanism not only significantly reduces dependence on virgin minerals but also significantly lowers the carbon footprint of each component, providing concrete environmental data support for our customers' supply chains. We care not only about the strength of the material, but also its "green strength."

Process Innovation - Green Wisdom for Waste Reduction

The core of environmentally friendly manufacturing lies in efficiency and waste reduction. Tung Shuhn spares no effort in process optimisation, especially demonstrating outstanding results in waste reduction:

Friction Stir Welding (FSW): Compared to traditional fusion welding, FSW is a solid-state welding technique that requires neither high-temperature molten metal nor filler materials. This technology not only significantly saves energy but also produces zero waste, making it particularly suitable for critical components such as electric vehicle batteries, which require extremely tight sealing. It eliminates flare and smoke, creating a safer and cleaner production line environment.

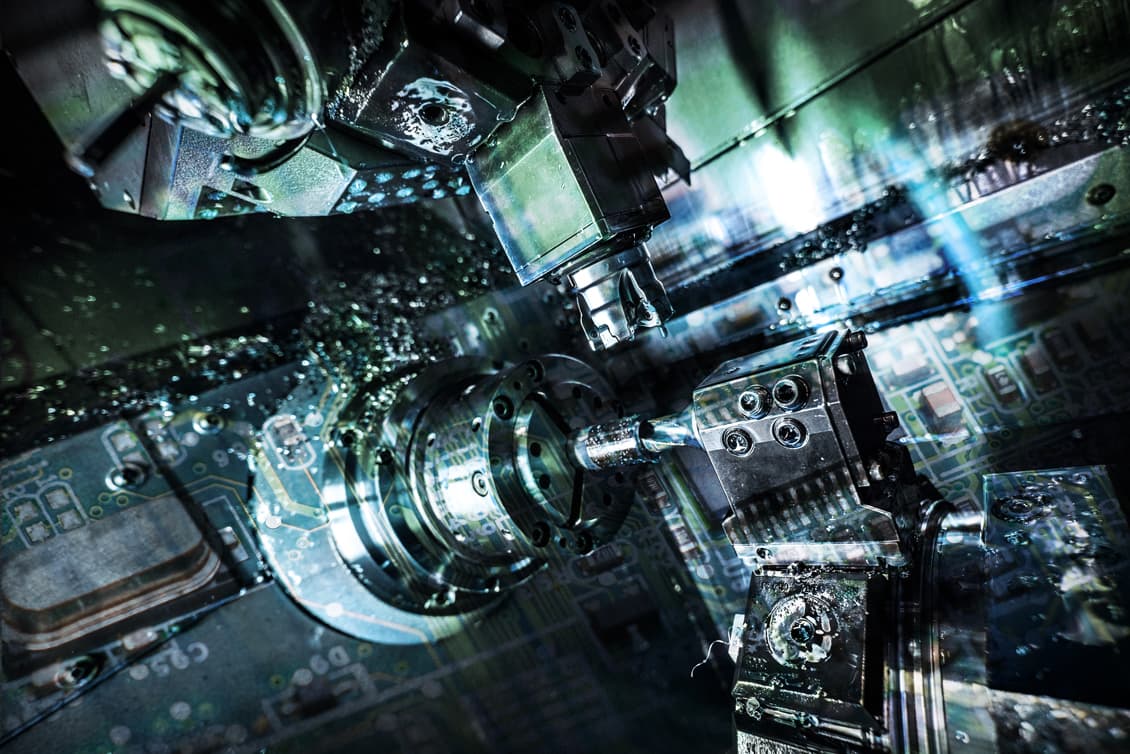

CNC and Die-Casting Optimisation: Advanced CNC path planning and precision tooling design maximise material utilisation. In aluminium die-casting, mould design optimisation (DFM) controls shrinkage and machining allowances at the source, significantly reducing subsequent processing waste. Precision manufacturing is inherently green.

Beyond the Production Line: A Sustainable Commitment to Green Packaging

The philosophy of environmentally friendly manufacturing extends to product packaging. Tung Shuhn actively promotes a green packaging strategy, using 100% recyclable and reusable packaging materials and collaborating with supply chain partners to explore packaging recycling systems. This not only reduces plastic waste but also improves transportation efficiency and reduces the carbon footprint of logistics through optimised packaging design. Every packaging choice represents a commitment to the environment.

Partner with Tung Shuhn: Creating a Green Future for Electric Vehicles

Tung Shuhn Precision firmly believes that sustainable development isn't just a slogan; it's a concrete practice rooted in every production process. As a pioneer in Taiwan's electric vehicle parts manufacturing, we not only provide high-quality components to leading international brands like Tesla and Gogoro, but also strive to become a trusted partner in your green supply chain.

Your products deserve high performance and sustainable DNA. Contact Tung Shuhn Precision today to explore how we can transform your electric vehicle parts needs into cost-effective, environmentally friendly, and green solutions!